280 Iowa Acres: The Frank & Amy Johnson Lindgren/ Gilmore & Hazel Family Farm

by Jon Gilmore Lindgren

September, 2020

A history of the Frank/Amy Lindgren family was influenced in many ways by this farm in North Central Iowa. Both Frank Lindgren and Amy Johnson had family in the area. The farm, then, might be a story that was repeated by a host of other relatives who made a living and raised families very close to the Frank/Amy farm. Many descendants still live in the area.

The farm is located about 70 miles northwest of the Iowa State Capital, Des Moines. These acres are in Greene County and one mile south of the village of Lanyon. Ten thousand years ago a huge glacier formed in central Canada and moved slowly through what is now the Midwest of the United States. The glacier rearranged the terrain, caused water to run in various directions underneath it and formed lakes as it melted. Most of the terrain today is flat or gently rolling. The soil is mostly rich and its productivity added by quite reliable rainfall. I’ve read it is among the most productive farmland in the world.

When Frank/Amy bought the land around 1914, it had been owned by several people in earlier years. The farm was 280 acres less the roads surrounding it. At the time this was larger than most of the surrounding farms. They were taking on an economic challenge. Farm prices were so low during the Great Depression that they almost lost the farm. The former owner could have foreclosed and retaken ownership. Instead he allowed Frank/Amy financial flexibility and they were saved from what would have been a farm failure.

In spite of those lean years, the farm served them well. They raised eight children whose lives no doubt were set to some degree by the income and experience from the farm. This, in turn, influenced the lives of grand-children and their children to this day. Gilmore/Hazel bought the farm from Frank/Amy in the early 1940’s and lived there for about 40 years. They raised four children whose lives were set in directions influenced again by the income from the same farm.

I am the youngest son of Gilmore and Hazel. I, of course, lived on the farm from birth to my High School graduation in 1956. I returned to spend a summer working there in 1962. Decades later after father Gilmore died, my mother asked me to manage the farm. I dealt with the family who then rented it, sold the grain (which was the rent my mother collected) and other tasks. I don’t claim to be an expert in agriculture nor am I certain I remember some details correctly. If other family members can correct me I would be most grateful. After mother Hazel died we heirs sold the farm.

This is an essay about some of the economic aspects of the farm and farm life. In doing so I’m hoping to reflect on what Frank/Amy and Gilmore /Hazel might have talked about, worried about and celebrated on this farm. All of us during our careers think about our work at work and often think about it when not at work. Farmers surely are no different. Details of day-to-day work about running a farm are what they must have thought about.

The “Minnesota Lindgrens,” Bruce, David and Steve, asked some insightful questions about the farm in our on-line conversations. Perhaps others would find interesting how some aspects of the farm, and most all farms of that time, worked. The following are some random minutia of the farm’s operation.

While farms then had big gardens and families ate some animals they raised, a lot of farm life was guessing what the markets for their products were going to do next. Grain and livestock prices fluctuated widely. Weather made for good and bad crop yields. Conventional wisdom of farm management went something like this, “Prices and weather are unpredictable. I need to hedge my bets. I’ll do that by planting a few different crops. Some of the crops will be marketed in the form of livestock–I will feed some grain to animals, then sell the animals. If the animal prices are high, I’ll get more for my grain that way. I’ll sell some grain to the local elevator. If weather/crops are good, those prices will be low–bad crops will raise prices. Livestock has the added benefit of putting some land into forage crops like hay, improving it for later crops and returning manure to the land.”

Frank/Amy farmed during the period when tractors began to replace horses as sources of power to raise crops. Gil/Hazel farmed when chemicals for controlling weeds and insects were common. Hybrid corn was developed and used, instead of holding back grain for seed. Medicines for animal diseases were common by the Gil/Hazel time. These influenced decisions and market prices.

Over the history of the farm was the Great Depression, terrible prices, and World War II, very high prices. Other economic cycles came and went.

A farm, of course, is a small factory, producing grain, meat and eggs. Within the farm factory are sub factories for producing each of the products. It used to be said farm life was good because of the variety of work. The family went from producing one thing to another as the seasons changed.

I’ll here go into some detail about a few of the sub “factories.” There were buildings and machines that allowed the farmer to produce more than he/she could have otherwise. The first is the “corn crib.” This was a building designed to accept the grain during harvest and move it out, when it was later sold or fed to animals. The corn crib, built by Frank and later used by Gilmore, was a somewhat complicated and efficient marvel.

Some of us have speculated about how Grandpa Frank came to build this particular building. One possibility was the Sears and Roebuck Catalogue. Sears started selling plans for houses and I suppose other farm buildings about 1910. A few years later it started selling precut kits. In this case the lumber would have been dropped off by a train nearby. On the web I saw an 1928 version of the catalogue. A “corn crib and granary,” very similar in profile to the one on our farm, was by then $887.00. This one did not have the interior elevator that Frank included in his more advanced version.

Another source of plans might have been Iowa State Agricultural College. The Extension Service was created about 1915 to disseminate technology developed at agricultural colleges to farmers. Each county had an Extension Office and plans could have come from there.

Yet another possibility is that the company which sold the elevator used in the building may have provided blueprints needed to use its product. In any event, a fine building was the result.

THE CORN CRIB

The Lindgren corn crib is long gone but the picture is of one very similar. The sides are made of wood with spaces in between them. This was for ears of corn. The corn would have too much moisture to store well when it came from the field. Air passing through the slots would dry the corn which would later be shelled and fed or sold. Pigs could eat the corn right off the cob so pigs saved some time and money.

The tall flat area above the door was an area to store grain. That was oats, soybeans and shelled corn on the Lindgren farm.

The building worked like this. The door facing us was two sliding doors that opened. The tractor and wagon drove into the space. The driver would stop at the proper spot and walk behind the wagon. He would pull down a flat conveyor feature that would fit just under the back of the wagon. A switch started chains and angle irons on the conveyor, as well as a larger elevator with buckets going up to the cupola at the top of the building. Driver would then open the back of the wagon and grain would move on the conveyor to the buckets that would carry the grain up to the cupola. There it would be dumped into some u-shaped slides and gravity would dump the grain into one of the bins or into the slotted side rooms.

When the grain was to be sold or fed, a sliding door at the bottom of the bin would let the grain fall into a waiting wagon.

For all of its advanced qualities, the corn crib was not a building any of us would want to spend time in today. It was dangerous, with its ladders and chains running near farmers (or their children). The grain bins in the top had little ventilation. Lots of hard shoveling was required to empty them. It was so dusty I once had a brief bout of “dust chills.” This was an ailment caused by dust and common among farmers. The symptoms were flu-like and some farmers had permanent lung damage from grain dust.

Corn cribs like the one Grandpa Frank Lindgren built were victims of unrelenting change in farming. Yields increased so much that a building like that one would hold only a fraction of the farm’s grain. Combines that shelled the corn in the field replaced the slotted bins. More speed in moving grain required bigger equipment.

But the corn crib helped two large families make a living for several decades.

Frank Lindgren installed the conveyor and elevator system described above by Jon Lindgren. Jon’s brother Dick, prepared a series of illustrations to depict how the conveyor and elevator functioned in the corn crib.

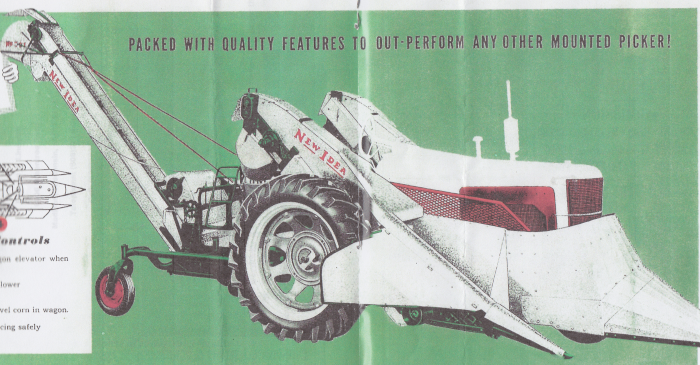

Frank Lindgren also invented and patented a tractor-mounted loader, which he manufactured. The following document provided by Dick Lindgren provides the drawings submitted with the patent application.